The next time you gaze at an aircraft flying above, you might be witnessing the future unfolding. Those streamlined jets slicing through the air aren’t constructed like airplanes were merely two decades ago. Instead of bolted metal, modern aircraft use fiber and resin. This isn’t the airplane building of your grandfather’s era. Engineers created strong, lightweight materials by weaving fibers with resins. It’s like a feather versus a bowling ball, but the feather can lift more.

The Building Blocks of Tomorrow’s Aircraft

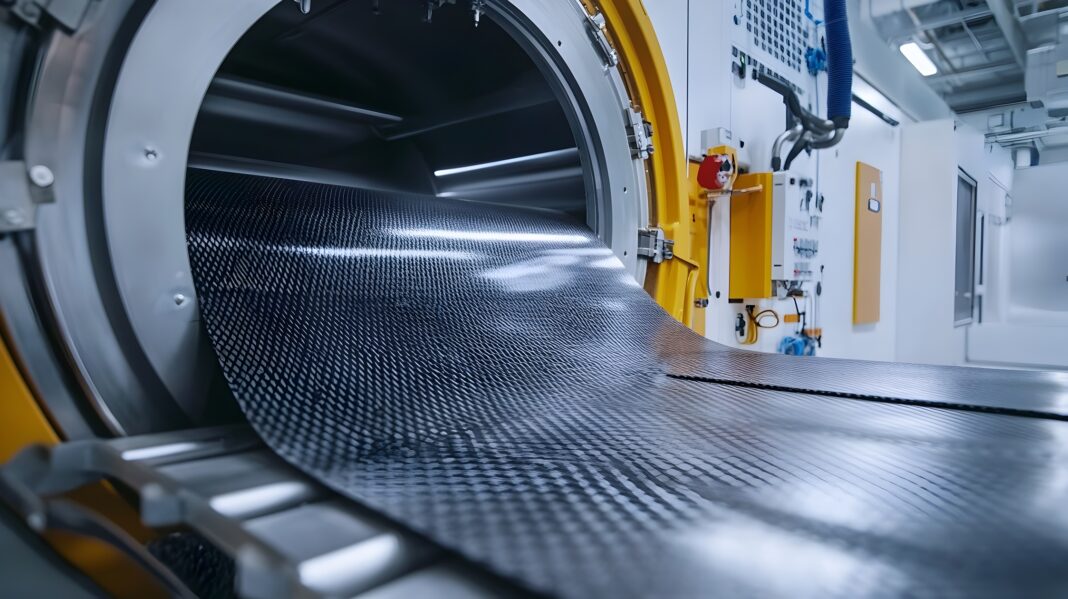

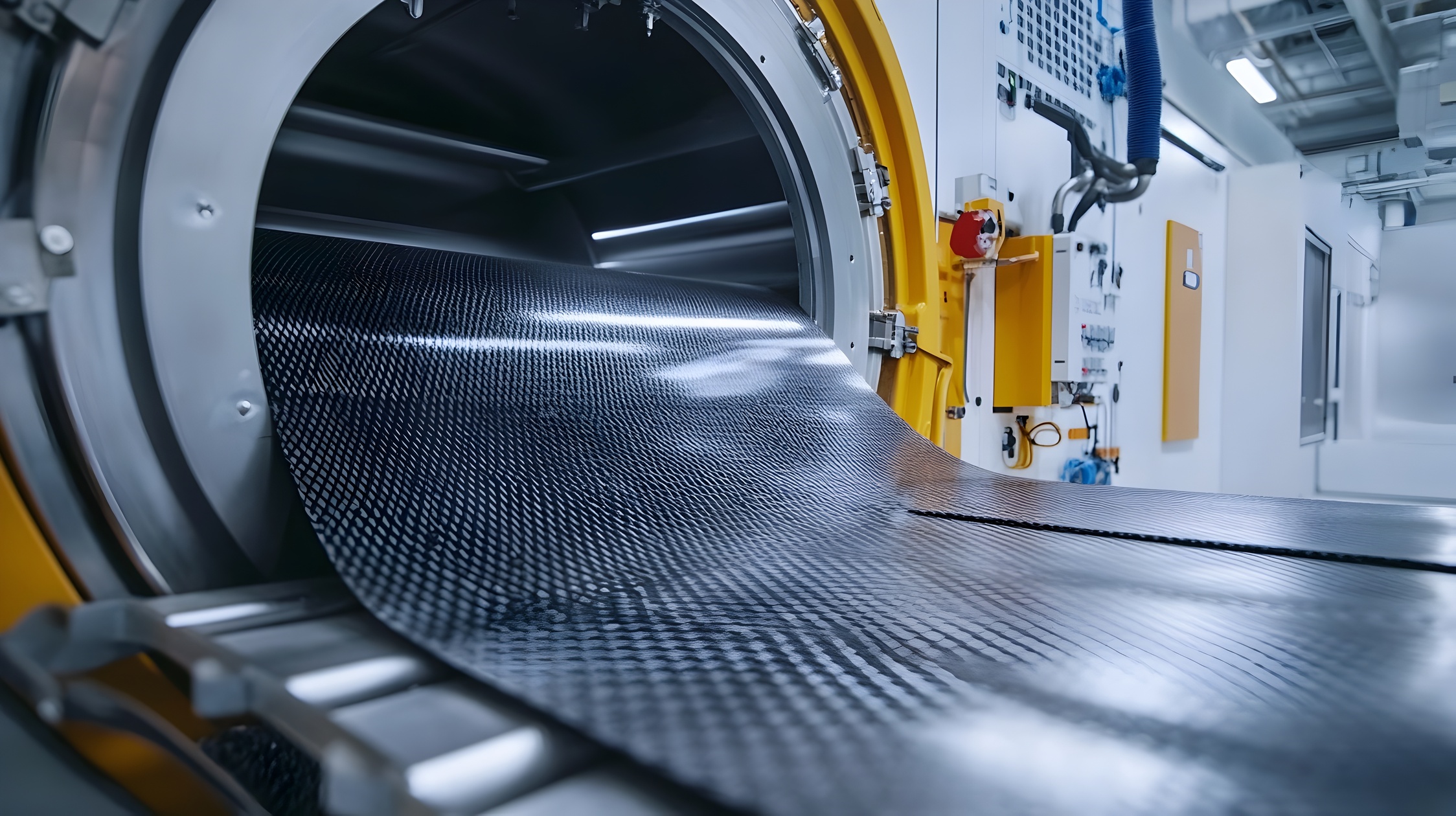

Think of making papier mâché, but with carbon fibers and resins. The process seems simple, but the results are unusual. These fibers are arranged in particular patterns, somewhat like how a skilled chef layers components in an ideal lasagna. Every layer has its function. Some offer strength in a single direction, while others manage various forms of stress. When engineers treat these layers with heat and pressure, they produce something extraordinary.

The completed item has a weight that is much lighter than conventional metal components. However, it can withstand forces that would obliterate traditional materials. It’s the contrast between attempting to snap one piece of spaghetti and attempting to snap an entire bunch.

Why Weight Makes All the Difference

Every bit counts when you’re aiming to overcome gravity. Airlines have been aware of this for many years. They’ve taken out magazines from seat pockets. They have also opted for lighter meal trays and even altered the design of seats to reduce weight. Yet, those changes are like rearranging deck chairs versus redoing the entire deck. A lighter plane needs less fuel. Less fuel use means lower airline costs and fewer emissions. Everyone gains.

The reductions in weight accumulate quickly. By substituting hundreds of metal components with fiber options, you could save thousands of pounds for each aircraft. That’s like taking out a compact vehicle from each aircraft before it departs.

Strength That Defies Logic

These innovative materials not only have a lower weight, but they also frequently exhibit greater strength than their predecessors. Metal components may form small fractures that expand gradually until a failure occurs. However, materials based on fiber respond to stress in a distinct manner.

Consider it in contrast between a chain and a rope. Sever a single connection in a chain, and everything collapses. However, if you sever a few threads in a rope, it remains intact. According to the experts at Aerodine Composites, aerospace composites function similarly to that rope, spreading stress over thousands of separate fibers.

Building the Planes of Tomorrow

Producing these sophisticated aircraft demands entirely new methods. Rather than welding and riveting metal parts, workers now arrange fiber materials in large molds. The procedure resembles crafting a massive sculpture rather than constructing a machine. This change has resulted in completely new roles and abilities. Laborers acquire skills to manage substances that act quite differently from conventional metals. They excel in methods that would have sounded like something from science fiction only a generation earlier. Quality control has progressed as well. Engineers use advanced scanning to inspect components. They detect problems unseen with old methods.

Challenges and Opportunities Ahead

This change presents challenges. These materials are more expensive upfront. Specific repair tools and methods are needed. Aircraft recycling poses new challenges. But the benefits outweigh the problems. Costs fall with increased production and better methods. What was once expensive is now standard.

Conclusion

New materials are changing how we fly. Fiber and resin composites are making aircraft lighter. They are also making them stronger and more efficient. With the advancement of this technology, there’s a chance to improve flight safety, cut expenses, and support environmental sustainability. The future is being built, one thread at a time.